Technology- based businesses – the company’s DNA

Source: Jone Torsvik, Statoil. From top of the direct drive test turbine on Havøygaavlen in Finnmark in Nortg Norway- an excellent full scale test laboratory

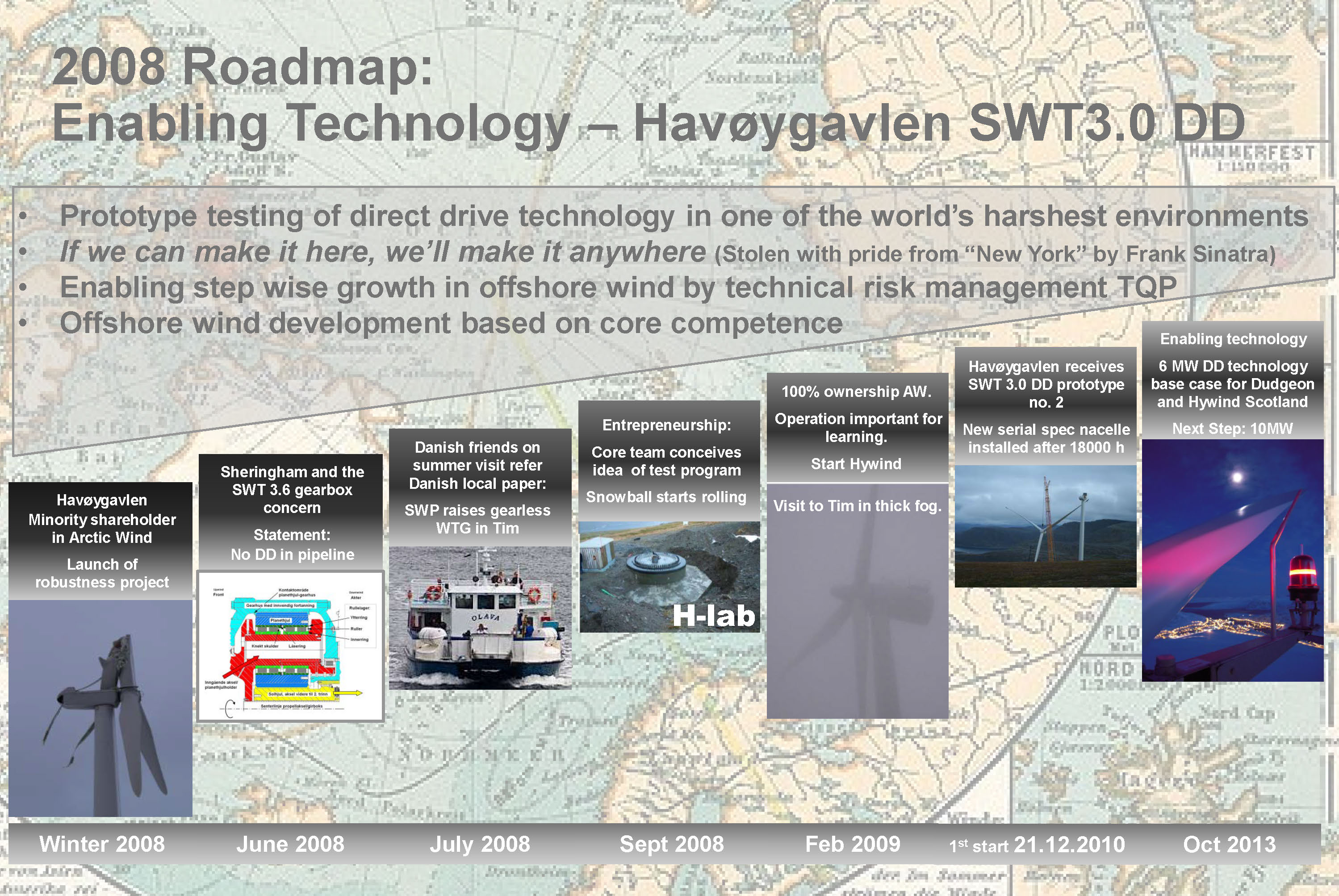

The small history below is taken from one of the harshest wind parks in the world. The site in Finnmark (Norway) was in fact a full scale test laboratory under extreme gusts and turbulence, where new wind turbine technology (direct drive technology) was tested and improved at an early and critical stage. This improvement was a very important contributor in order to reduce the cost of electricity by 40% in 5 years. With this new technology platform, Statoil had insight into the risks of the inmature supplier industry. Then Statoil was positioned investing in several huge and attractive offshore wind projects to come, two of them starting up in 2017. The company was well positioned for growth. Not only as a traditional oil and gas company, but also an important renewable company where the business is attractive.

In 2008/-9 there was much skepticism w.r.t. the business potential of renewables within the traditional oil & gas company Statoil. At that time one of the key challenges in the wind industry business was unreliable and expensive wind turbines, which could lead to lack of new projects due to poor profit within the wind business. The offshore turbine market was very challenging, a real risk was not developing large and cost efficient offshore turbines in time. In other words, the offshore turbine developing cost was huge and market too small – a long way to go to reach a matured market. Together with a dedicated core team, Haglerød was heading the project which scope was to test the new, promising and robust direct drive wind turbine (pre-series, number 2) from Siemens Wind Power in a harsh environment in Finnmark in Norway – from idea to finished project. On Havøygavlen there was a blade break down leading to decommissioning of a Nordex turbine, and the timing was excellent for introducing a new and promising direct drive technology from Siemens Wind Power, supported by the Norwegian government. After a lot of challenging work, the 2 years test program leading to several break- downs and consequently improvements, the program was accomplished successfully!

The commercial projects could then use this as a fundamental basis, in order to evaluate the technical and financial risks in due time. The most vital learnings were taken into account. Later on, Statoil sanctioned 3 offshore wind parks for several billion NOK with this wind turbine platform, scaled up from 3 to 6 MW (132 units, 817 MW, total project cost 25-30 bill EUR) which is soon to be completed (Dudgeon 67x6MW, Hywind Scotland 5×6 MW, Arkona 60x6MW together with E.ON). Cost of electricity for offshore wind was reduced with 40% in that 5 year period (Teknisk Ukeblad 19.9.17) . The wind turbine is now a commercial success, upgraded to an offshore 8 MW Siemens -Gamesa machine. One are now already talking about 13-15 MW each turbine. A few more offshore turbine suppliers have entered the market. This will bring cost of electricity further down, and the offshore industry might probably not need any support schemes in medium term. Many factors and persons are contributors to this succsessful development. However, one can argue that this innovative technology team work at Havøygavelen, has made a huge difference! Probably the most important contributor improving the profit that one are harvesting today.

The work was also very much appreciated from the wind turbine supplier Siemens:

Former Chief Technology Officer Siemens Wind Power, Henrik Stiesdal January 2016: « It was a good project on Havøygavlen! We were lucky that you were our customer in order to be the «early mover» on the concept. I was informed a short while ago, that Siemens 7 MW, which is just an upscaled Havøygavel- wind turbine, was selected at the wind turbine of the year in 2015 – it would not have happened so fast, if you were not there. Best regards Henrik.»

Until 2014, Stiesdal was the Chief Technology Officer of Siemens Wind Power, and he is regarded as one of the fathers of the modern wind power.

What about the future for wind power?

Still cost of electricity cost for offshore wind cost around 1 NOK/kWh (OPEX and CAPEX), and attractive cases will probably be reduced to around 0.7-0.8 NOK/kWh in the few years to come), primarily due to scale effect (turbine size, 8-9.5 MW machines under testing in 2017) as well as improved robustness, improved offshore accessability and real supplier competition. With established additional support, the business is attractive.

Attractive onshore wind sites with modern turbine have much lower cost of electricity, in the area around 0.3-0.5 NOK/kWh. The support schemes are also lower. Of course, multi MW turbines cannot be transported onshore, so there are physical limits w.r.t. scale effects. This means that very good sites near the market where electricity prices are high does not need any support schemes – but this is not the case for sites in especially the Nordic countries with low electricity prices.

Is all this an issue for specially interested people? No!

Of course no wind energy can be produced without wind, and no solar energy be produced during the dark. However, it will be very interesting to follow the rapid technology development and cost reductions of battery and solar technologies. Energy efficiencies both at producers and consumers (peak shaving technologies, Internet of Things, big data as well as continuous improvement), and energy mix will all make the energy market dynamic. In the long run it will be more sustainable, cleaner and more cost efficient. And, not to forget, improve the standard of living for billions of people on this planet.

Several years ago it was reported that coal was beaten in UK (w.r.t prices). Later the production from windy and sunny days in UK and Germany was more than the electrical needs those days.

Source: By Jone Torsvik and Klaus Haglerød.

Figure above illustrate the roadmap: Typical succsess criteria for start-ups are: Very good idea, very attractive business case for future growth and the right personnel with capability and stamina to implement; (resisting the hundreds of potential show stoppers.) For this case one might add very challenging and capital intensive supplier industry, scaleability issues, promising (disruptive) technology , and not to forget team work and the essence of timing. It was experience transfer from subsea technology as well as onshore to offshore environment. This case was a mix of all these factors, established under a road map.

I am very grateful for all the very good cooperation and team work. A book should be written about all this history! Many names could be mentioned for all the good spirit and team work in a challenging supplier industry; however I have to list the most important: Today CEO Finnmark Kraft Egon Leonhardsen. Thorbjørn Ulriksen (Rambøll Energy) and Jone Torsvik (Statoil) for the birth of the project on the way to Husum Wind Conference in 2008, and all the work establishing and following the project. And not to forget the management that supported this concept, as well as the technical core team consisting of Jone Torsvik, Vidar Berge (Statoil) and me. Mr. Torsvik is today working as a PhD student at NTNU going even deeper within this important technology.