11. Norsk Hydro and Statoil. Rotating machinery – operational & diagnostic centres

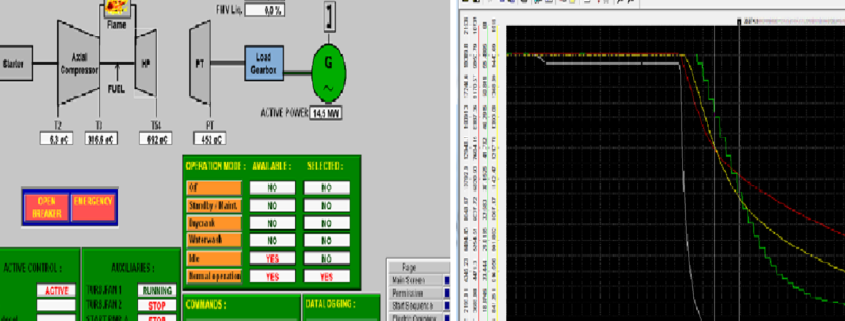

Source: Woodward fuel controller for gas turbines. Very fast (mS), safe, and power ful diagnostic capabilities – very good reputation among the skilled controls and mechanical engineers.

Operational & diagnostic centres

Our small team at that time in Norsk Hydro around late nineties (Porsgrunn, later Bergen) was one of the pioneers what is many times explained as “Operational Excellence” today. Much can be said about this. However, the point was bringing the real time data (first of all vibration) to shore from rotating equipment. Then we could make analysis and diagnostics from the office, before they even knew the condition offshore. Based on team work offshore – and onshore, one could state the actual health condition to the rotating machinery. This was useful for the planning of the right things to be done in order to avoid a break down, or even still operate with right measures taken in time. Typically a outage of one compressor train a day cost around 10-25 mill NOK (delayed cost), where the “heart” of the process plant were rotating equipment. The start was collecting online data from primary rotaing equipment (in combination with offline measurement of secondary equipment), at the final stage all the 10 platforms. First with vibration, later on added with process data and with many different control systems. Statoil brought this to the next level with via “Integrated opeations,” and established several rotating equipment centres. The same was happening within the Oil & Gas industry. Elements from this was adopted within the wind business in Statoil, and again today (2017) explained as “operational excellence,” big data or equivalent programs. A huge number (in average 80%?) of cash flow is generated by rotating equipment in oil & gas industry, the number is 100% in wind industry. It will be very interesting to follow all the further refining of algorithms and analysis techniques the years to come; both as condition based maintenance as well as active controlling the equipment w.r.t. loads and life time expectancies.

Typical overview of important systems for a typical “compressor turbine”:

−Vibrations monitoring system (typically GE/Bently Nevada, B&K, also seen implemented into SAS system -ABB)

−Performance monitoring

−Offline/online oil monitoring

−SAS (prosess in different versions and samplig rates, time delays, graphics and dynamics)

−Fast logging system from turbine fuel controller (first out identifier/error code, mS resolution) “Control assistant” or equivalent.

– Anti surge controllers for the turbo compressors (in the last years from time to time implemented into SAS system)

GE Bently Nevada ADRE data acquisitoion system extended use of vibration and process data signals during task forces, throuble shooting og when there are good reasons for fast data.

This technology was partly adopted to wind industry. But the situation is not the same, due to the fact that wind turbines are normally not manned as the oil & gas platforms, and the contract setups and warranty periodes (operational model) are not comparable.